The tool and cutter grinding machine you own needs filtration systems. They contribute to the continued flawless operation of your device, which benefits your company. Quality matters the most when buying an end cutter machine or a surface planner machine. So today, in our blog we will talk about the filtration systems that can ruin your grinder and where you can buy one. So stay tuned.

Using your equipment and cutter grinding machine with zero filtration

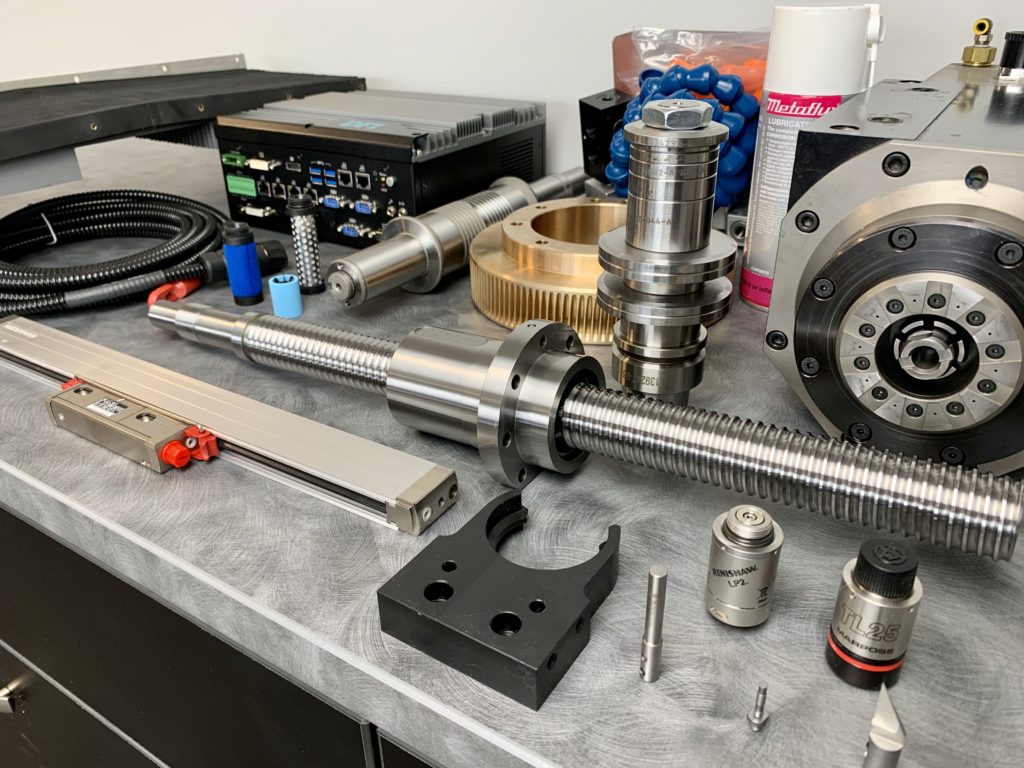

A tool grinding machine’s fundamental concept is the utilization of high-pressure oil. The oil prevents overheating, failure, and deformation of the cutting components, such as the grinding process and blanks, by keeping them cold. In the absence of grinding oil, excessive heat is generated, and the cutting process will never satisfy the requirements for excellence.

Before returning to the machine tank, the oil in the grinding zone needs to be filtered. Your oil needs to be filtered since it will have little HSS or carbide particles in it (high-speed steel). These particles seriously harm your tool and cutter grinding equipment when combined with oil. Your crushers and discs will degrade far more quickly than you would expect when this occurs, which will increase your additional maintenance and substitute expenditures.

The majority of cutter and chop manufacturers only include an oil-gathering tank with their machines. The same black oil that is loaded with carbide and HSS returns from the grinding zone. Because of this, cutting tool manufacturers must be extremely careful, aware of this, and prepare to build an efficient filtration system straight away.

Using a filtration system using paper bands

An inadequate method of filtering grinding oil is with a paper band filtration system. You cannot employ a filtration mechanism worse or more useless than this one. Particularly for applications involving tool and cutter grinding, some could contend that using a paper band filtration system is preferable to having no filtration system at all. The grinding oil contains tiny carbide/HSS particles. Only about 10 microns make up 80%. The design of the tissue band filter prevents pressure build-up. As a result, during filtering, there isn’t any compressing motion. Now, the filter paper’s smallest opening could be no more than 10 microns wide. That does not, however, imply that every opening on the material is smaller than 10 microns. Therefore, the permeability of the paper affects how well it filters.

Using a centrifuge to remove HSS and carbide

Centrifuges are not a viable alternative if you want to screen away tungsten and HSS from your grinder. These are not filters, as you can see. Devices use a circular motion to separate the suspended solids from a stream rather than a filter medium to do so.

Therefore, utilizing a centrifuge system to remove 1-micron pollutants from the crushing oil won’t be effective. The result will be clear oil that is nevertheless loaded with HSS and carbide.

However, how would you retrieve carbide? The centrifuge is the finest option. They function like a kidney, taking in contaminated oil and returning clarified oil to the original tank. In this method, you may examine the oil in your tank to see how clean it is; if it’s dark or blackish (which indicates the presence of carbide or HSS), you can determine what has to be changed.

One more thing that has to be mentioned is that a centrifuge superheats as it spins. Therefore, use caution while utilizing this procedure if your product is thermally-sensitive, which is true for the majority of carbide-cutting tool grinding!

Hence we always say to buy machines from trusted sites. For example, Dhanjal Mechanical. They literally have everything from switch board cutting machines to wood surface planer machine. They are quite famous in the manufacturing field.

Bag-filter system

The paper band filter is still a risky proposition, but the bag filter is an improvement. For the purposes of this article, let’s assume that the filter medium utilized in these systems is unable to produce sufficient resistance to capture the tungsten / HSS dust.

The bag filter system is used by cutting tool manufacturers because it is inexpensive to use, but it also has a lot of drawbacks. Bags require regular cleaning since they are unable to produce enough resistance to capture the carbide or HSS dust and it is known to be massive time-consuming. Therefore, manufacturers who utilize bag filters to filter out tungsten or HSS particles face a double penalty. The bag doesn’t filter oil to the necessary amount, to start with. The bags are also disposable. It’s significant to note that carbide begins to suffocate the bag pores, lowering the rating of oil production through the bags. There is currently no other choice but to substitute it.

Conclusion

Regular maintenance is important and so is purchasing the machines. We already 5told you about Dhanjal Mechanical. You can buy top-rated cutter grinding machines or circular saw machines. Also, check out their switch board cutting machine price.

More Stories

Everything One Needs to Know About FacFox

How to get the most out of your dedicated server and achieve peak performance

How To Ensure VPS Security With Root Access?